Enterprise Name: Huizhou Yosingying Innovation Materials Co. Ltd..

Website:http://cjcq.com.cn

Contact: Mr. Zhuang 13609663446

Tel: 0752-6618779

Fax: 0752-6618783

Address: Second row on the South Side of Fengwu Village

Section, Qiaoqi, Shiwan Town, Boluo County, Huizhou City, Guangdong Province

Classification and Selection of Common Furniture Bands

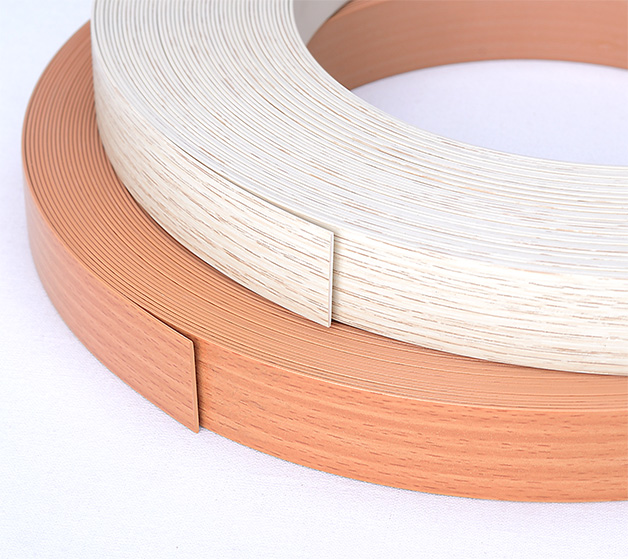

I. PVC seal

With polypropylene or polyvinyl chloride as the raw material, the wood pattern, permeable heart, plain color, two-color series of plastic seal strips made by mechanical pressure. PVC seal has the characteristics of heat resistance, oil resistance, strength, hardness, and high bending degree; Its surface performance is good, wear resistant, can be repaired; The surface effect is also good. Its patterns and colors can have natural wood colors close to logs, but also other color patterns. It is also the most commonly used seal bar in plate furniture production.

II. Leather border bars

The above good natural Birch, oak, maple, beech, cherry wood and other wood, processed by the machine cut wood thin sheet seal. The wood skin seal has the characteristics of natural, soft, invariable, and strong adhesion when pasting. However, because the seal is very thin(usually about 0.1-0 .3 mm), and the fiber density of different wood is different, the wooden seal also has a defect that is easy to fold and tear, but it can be treated by the back of the gel coating. Make up for the above defects. Usually the paint is sprayed(painted) after the sealing of the wood skin seal. Since the EVA furniture sealing edge hot melt glue and the solvent in the paint will produce a certain chemical reaction, which will cause degumming or falling edge. Therefore, the adhesive with relatively good performance should be selected for the sealing edge of the wood skin.

III. Three polydiamide seals

Print various art patterns(or plain colors) such as wood patterns, flowers, leather patterns, marble patterns, etc. on high-quality colored raw paper, and then impregnate the cured paper seal with modified cyanamide resin. Melamine seal has the characteristics of wear resistance, fire resistance, oil resistance, moisture resistance, acid and alkali resistance, and has excellent flexibility, strong adhesion after bonding, and easy to fall off. Melamine seals have excellent bending properties and are better when heated, but they have easily broken defects.

IV. ABS Edge Bar

ABS resin is currently one of the most advanced materials in the world. The seal made of it is not doped with calcium carbonate. After the trim, it appears bright and smooth, and it will never appear white. However, the market price of ABS resin is about 12,800 yuan/ton, and the production cost is high. In the market promotion, it is about one times higher than the price of PVC edge strips of the same specification. ,,

V. Advantages of PVC seals

1. : Pvc furniture is relatively light on the edge, which is relative to metal and organic glass. The reason for the lightness is not because it is a polymer compound, but because they are organic compounds, IE, lighter elements such as carbon, hydrogen, oxygen, and nitrogen.

2. : The material of the PVC furniture seal is plastic, which is easy to process. Plastics are plastic, that is, they are deformed after heating or pressurization, and they remain unchanged after cooling or pressure disappears. It can be processed into sealing strips of their respective shapes by means of extrusion, such as T-type sealing strips, H-type sealing strips, D-type sealing strips, V-type sealing strips, and workword shapes.

3. : The edge of PVC furniture is of good quality and cheap, and the price of plastic fluctuates far less than that of metal.

4. Detection Method

Visually check whether the edge bar is consistent with the color and texture of the plate used, or with the designer's requirements.

Check whether the surface of the seal is smooth and flat, and there are no miscellaneous points. If there are miscellaneous points or fine hairs, the pinhole may be made of recycled miscellaneous PVC. Check whether the back of the seal is flat. A flat blade can be used to hold the seal across the edge to see if it is in a straight line. If it is not in a straight line, thick rubber lines will appear on both sides of the seal. If the back of the seal bar is flat, there are still thick rubber lines after the seal can be checked as follows: Check whether the saw surface of the plate is flat. If the sawing is of different specifications, there are small steps on the sawing surface, affecting the sealing edge. Check whether the hot Sol coating is too thick. Check whether the thickness and pressure of the sealing machine are coordinated. Use a small section of the seal edge seal edge, and then vigorously tear, to check whether the seal edge and thermal Sol adhesion strength is reasonable and uniform. If there is not enough strength, check whether the heat Sol temperature of the sealing machine reaches the standard.

Whether the side of the plate after the trim is uniform, if there is a jagged tooth, it may be due to the following reasons: the trim knife is too blunt; The seal is too hard; The seal contains too much calcium carbonate. Using nails or other tools to mark the sealing edge bar, if there is damage, the surface resistance and hardness of the sealing edge bar do not meet the standards, proving that the quality of the sealing bar is not satisfactory.